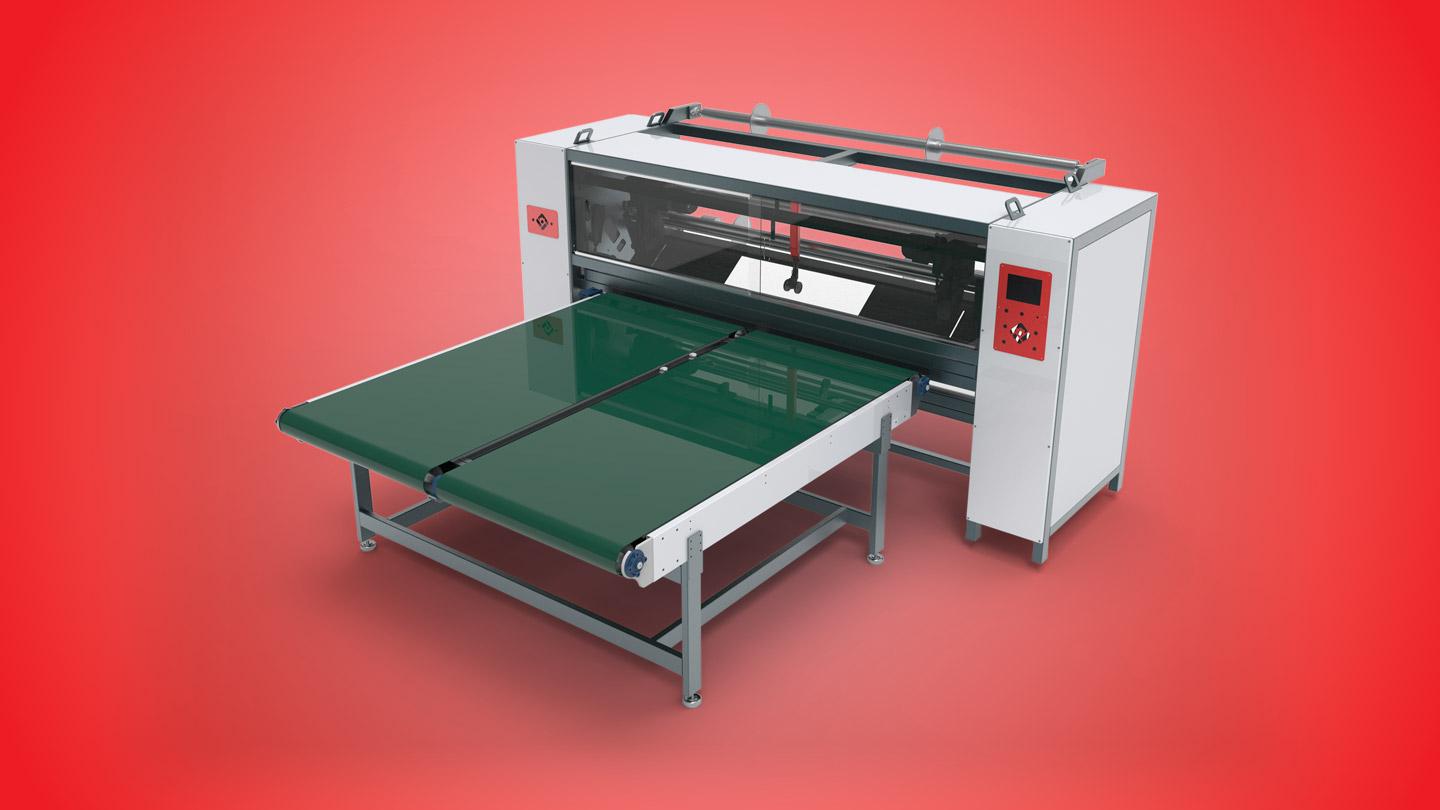

Automatic Quilted Panel and Border Cutting Machine

MT-CU/2000

FEATURES

This machine is designed for the cutting of panels and borders required in mattress production. It is positioned after the quilting machine and processes the panels coming out of the quilting process, making them ready for use.

Speed Adjustment and Precision Cutting

The machine offers speed adjustment options and ensures millimeter precision for superior border cutting quality.

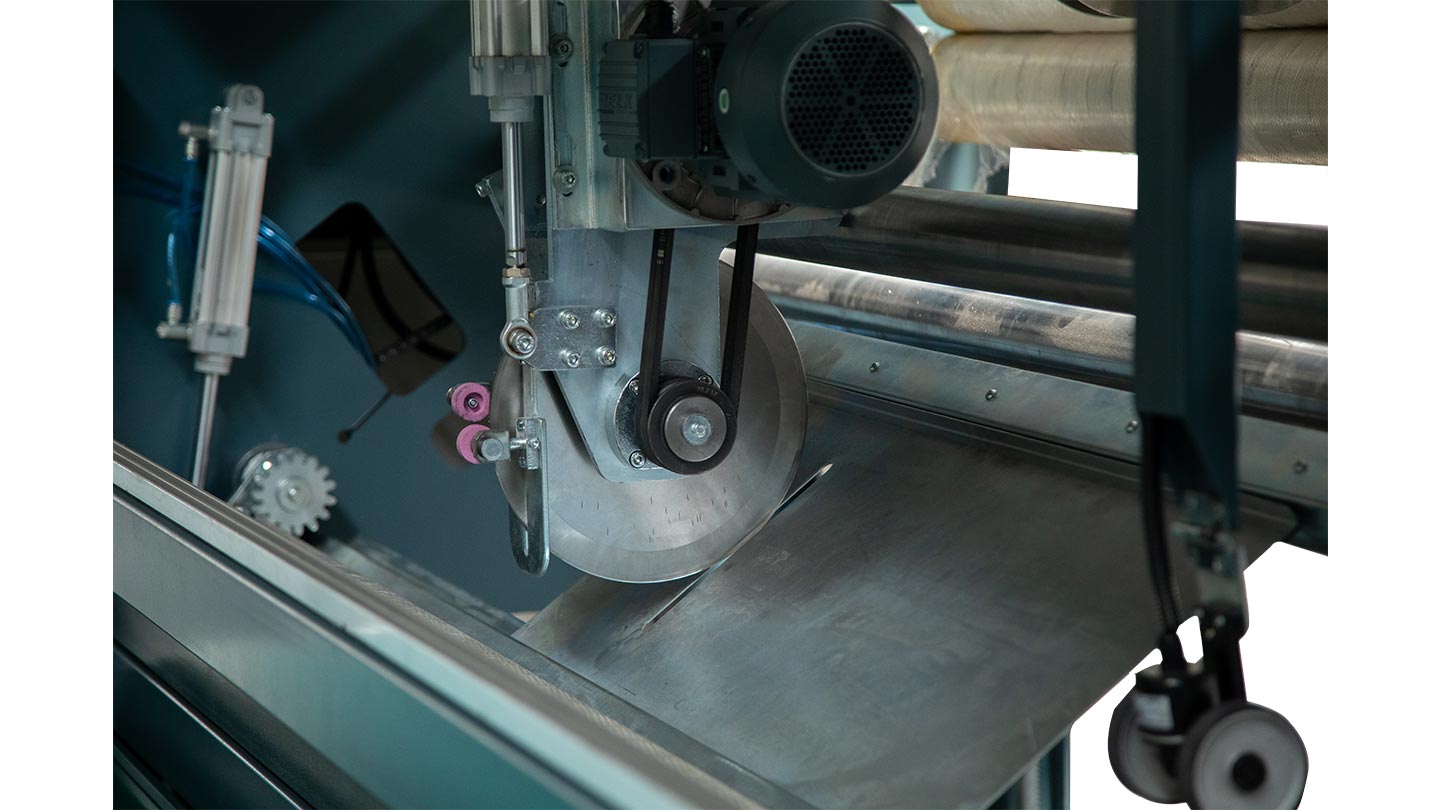

High-Performance HSS Blades

Equipped with 12 HSS (High-Speed Steel) blades that are resistant to high temperatures during cutting. These blades provide excellent performance and cutting quality, enhancing efficiency.

Customizable Border Sizes

Borders can be cut to the desired dimensions with the precise adjustment of the blades.

Synchronization with Quilting Machines

It works seamlessly with all chain-stitch and lockstitch quilting machines, thanks to its speed synchronization feature.

Roll Winding System

Includes a roll winding system that supports an uninterrupted and organized cutting process, enabling easy transportation and storage.

Ergonomic and User-Friendly Design

Designed with operator comfort in mind, making it easy to use.

Durability

Built for long-lasting use with minimal maintenance requirements.

Optional Feature

An automatic panel stacking machine can be added as an option.

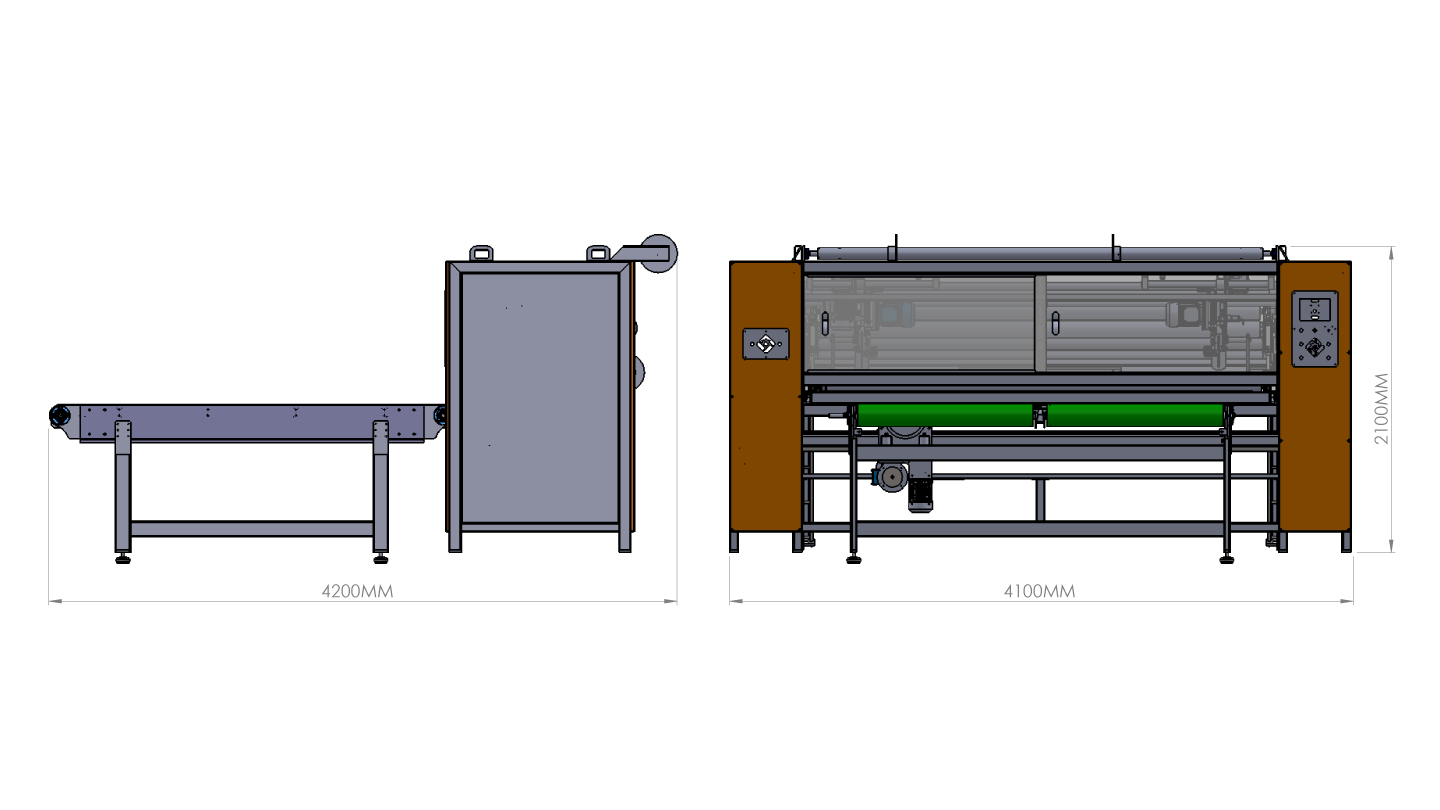

| SPECIFICATIONS | |

|---|---|

| Dimension | W: 4100 - L: 4200 - H: 2100 (mm) |

| Weight | 1000 kg |

| Conveyor Belt | PVC 2.7 Belt |

| Power | 4 kW |

| Air Pressure | 6-8 Bar |

| Electricity | 380 VAC (III+N+TT) |