You are here:

- Home

- Mattress

- Mattress Packaging

- Automatic Sofa & Base Packaging Machine

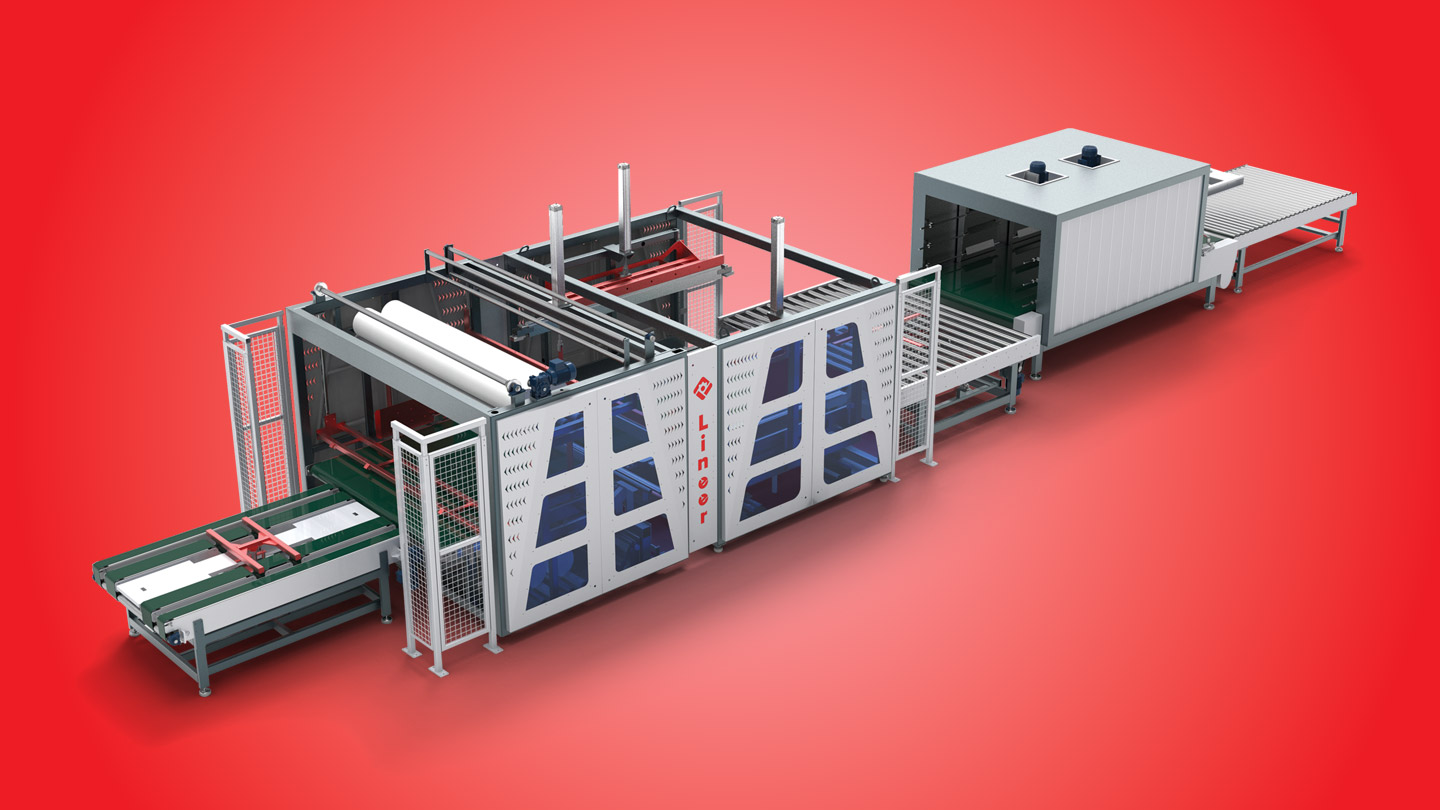

Automatic Sofa & Base Packaging Machine

MT-PG-B/6100

This machine is an automatic base packaging machine designed to cover bases that have passed quality control with polyethylene film.

Operation: In this machine, bases are fed horizontally into the system, just like in mattress packaging. The bases are automatically covered with packaging material in the packaging unit. The packaged product then passes through the oven unit, where heat is applied to the packaging surface. This process results in tight and secure packaging, preventing dust, dirt, and moisture from reaching the product, ensuring safe and durable storage

Quality Control and Carton Wrapping Conveyor:

The bases are subjected to quality control on the entry conveyor, after which the carton wrapping process takes place on this conveyor.

Water-Cooled Sealing Jaws:

These provide a more uniform seal, maximizing packaging quality.

Time and Cost Efficiency:

The packaging process requires no operator involvement. The fast and automatic packaging operation reduces labor costs and increases production capacity.

Advanced Oven Design:

The oven features heatinsulated and fire-resistant conveyor materials.

It is equipped with four 1500 kW cassette-type resistors and nozzles for uniform heat distribution.The sensor system ensures that the oven only operates when the product is detected. Two cooling fans ensure a smoother packaging quality.

Material Savings:

During the automatic packaging process, packaging settings and material choices are automatically adjusted without the need for manual intervention, resulting in a 25% reduction in packaging material usage compared to standard processes.

Adjustable Operating Options:

The conveyor speed can be adjusted via the control panel, and both single and double packaging options are available.

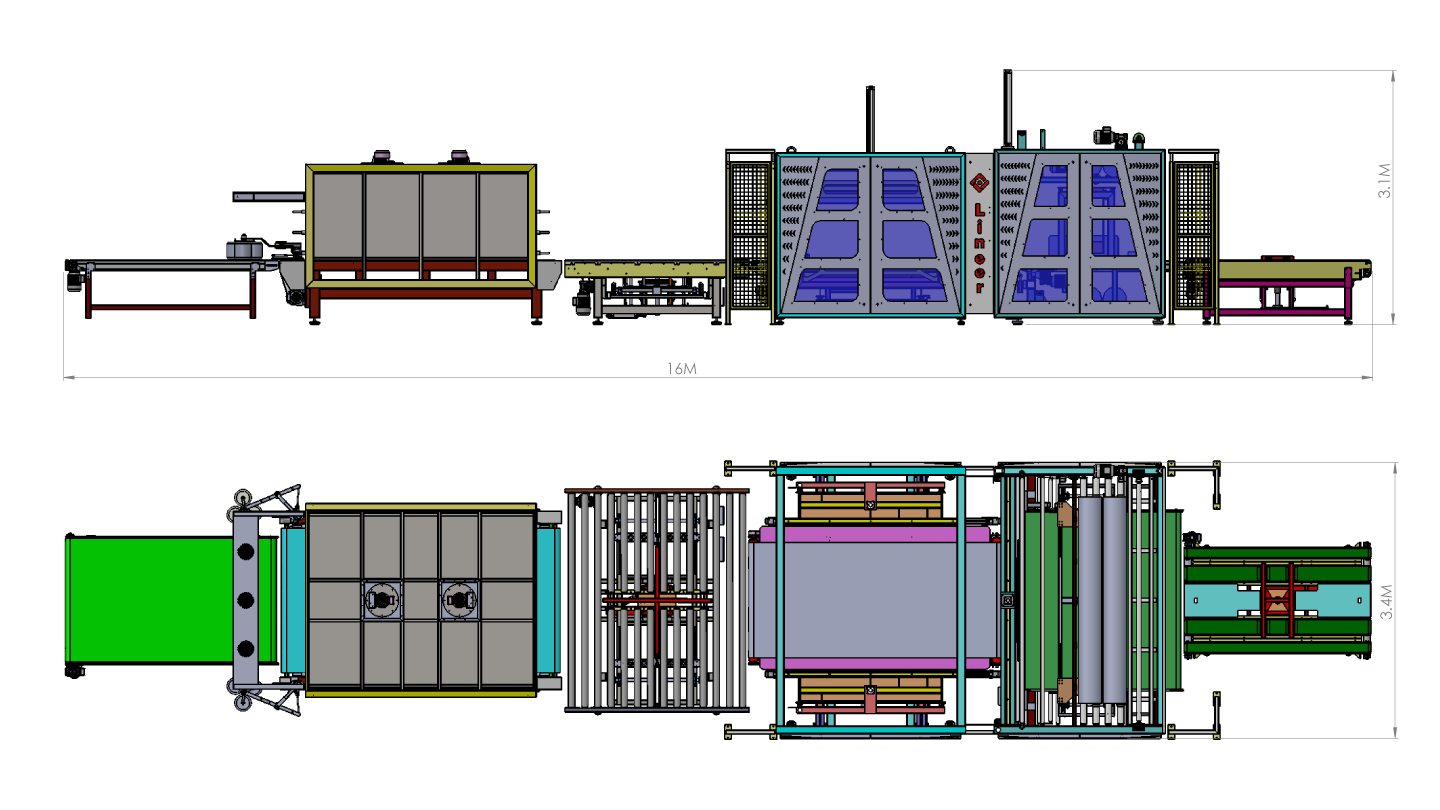

| SPECIFICATIONS | |

|---|---|

| Line Dimension | W: 3.5 - L: 15 - H: 3 (m) |

| Max. Product Dimension | W: 1200 - L: 2000 - H: 650 (mm) |

| Weight | 3200 kg |

| Capacity | 45 seconds/base (can vary according to the product) |

| Conveyor Belt | PVC 2.7 Belt |

| Power | 70 kW |

| Air Pressure | 6-8 bar |

| Electricity | 380 VAC (III+N+TT) |

| Oven Dimension | W: 2500 - L: 4500 - H: 1400 (mm) |