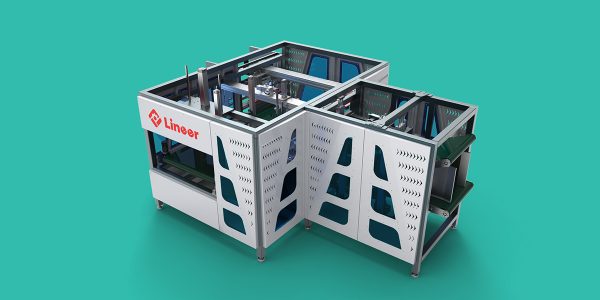

Ball Fiber Machine

PL-BFM/1100

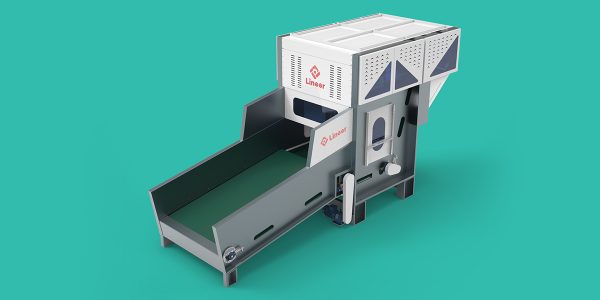

Space & Cost Efficiency

Combines the

functionalities of fiber opening and ball fiber

production into one compact machine, saving

valuable factory space and operational costs.

Touch Screen Control:

Facilitates quick

adjustments for handling different fiber types and

product specifications.

Integrated Process

Combines fiber opening

and shaping into a single, optimised step,

maximizing productivity.

Energy Efficient:

Operates with low energy

consumption while maintaining high output

capacity.

Versatile Fiber Processing

Produces fiber

balls from a variety of fibers, including polyester,

cluster, microfibers or blends of these materials.

Quiet & Stable Operation

Designed with

minimal vibration and noise for a smooth and safe

working environment.

Efficient Fiber Transformation

Converts

polyester fiber bales into small, uniform fiber balls,

ideal as filling material for diverse applications

such as garment, bedding, pillow, toy stuffing, and

other home textile products

Consistent Quality & Safety

Ensures reliable

performance and adherence to safety standards

for a superior end product.

Customizable Output

Allows adjustment of ball

size and feeding time to cater to specific product

requirements.

User-Friendly Design

Ergonomically designed

for easy operation, requiring only one operator to

run.

| SPECIFICATIONS | |

|---|---|

| Dimension | W: 1575 - L: 3500 - H: 1500 (mm) |

| Capacity | 150 - 200 kg/hour (ball fiber) |

| Power | 16 kW |

| Weight | 1650 kg |

| Electric | 380 VAC (III+N+TT) |

| Air Pressure | 6 bar |